Failure Analysis

Our vast inventory of lab equipment and scientific techniques enables us to verify device parameters, identify fault locations, determine failure modes and root-cause of failures in printed circuit boards, discrete components in a wide range of technologies.

By classifying Failure Analysis in three broad categories by degree of complexity, this allows us to detect failures as quickly and efficiently as possible. The results of each level of analysis are recorded in an appropriate report.

Watch our video on Failure analysis services.

Level 1

We quickly pinpoint the defect using non-invasive microscopy techniques.

X-Ray

Scanning Acoustic Microscopy (C-SAM)

Decapsulation and package opening

Visual inspection including optical microscopy and Laser Scanning Microscopy (LSM)

Level 2

When the defect is hidden, we localize it by using more advanced techniques to actually reproduce the failure in the lab.

Pin testing

Static DC biasing

Liquid crystal fault isolation

Emission Microscopy (EMMI)

Optical Beam Induced Current (OBIC)

Level 3

We determine root-cause by open-ended analysis, to gain understanding of the nature of the failure and its relationship to observed faults or defects. MuAnalysis undertakes each step in this Level 3 analysis only with approval of our customer.

Backside emission microscopy

Various optical techniques for fault isolation

Delayering or cross-sectioning

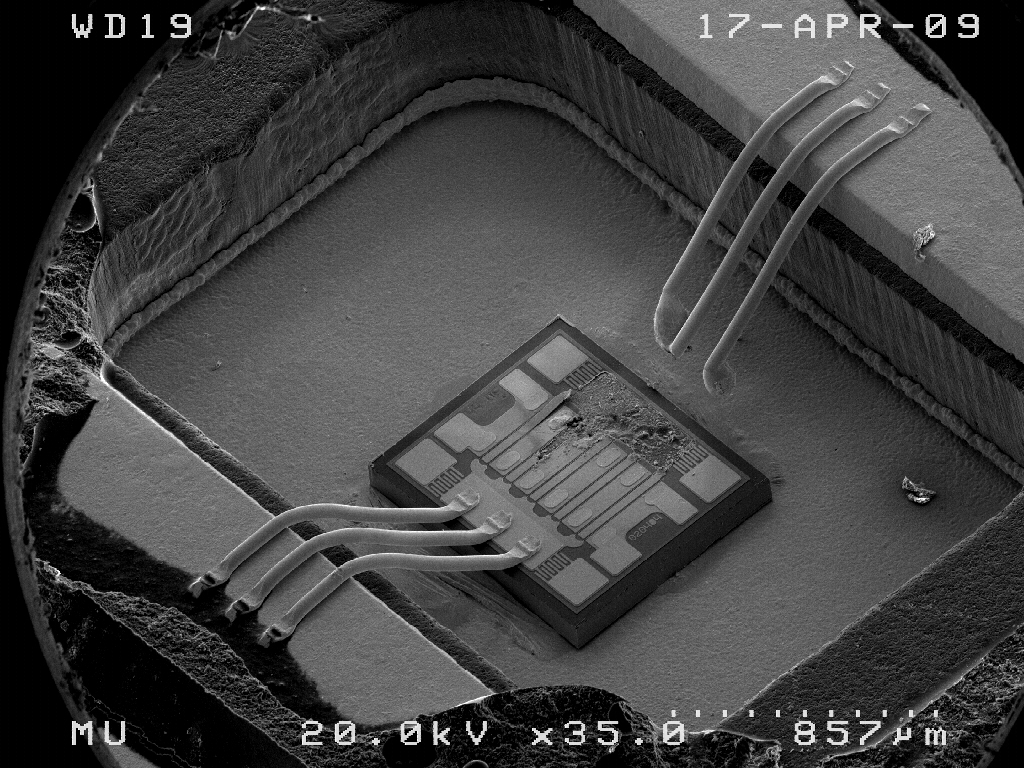

Scanning Electron Microscopy (SEM)

Microprobing, with picoprobes

BGA layer by layer construction analysis